When swapping engines, transmissions and/or transfer cases, you often need to use a transmission adapter to connect components. However, other issues can arise that hurt performance and longevity. Here are five common transmission issues when installing adapters and how to fix them.

Bellhousing Alignment

The Problem: The bellhousing protects the flywheel assembly, and it must be aligned accurately with the transmission input shaft. Alignment issues are more prevalent when doing transmission swaps.

The Symptoms: A misaligned bellhousing can lead to vibrations, shifting difficulty, clutch failure, clunking sounds and even engine damage. It may also void the transmission warranty.

The Fix: Check that the bellhousing mounting surface and engine block are parallel. Then mount a dial indicator and magnetic base to the flywheel. Slowly turn the crankshaft to sweep the bore. If the total indicator change is higher than 0.01 inches, adjust the bellhousing with offset dowel pins.

Using the Wrong Adapter Plate

The Problem: Every drivetrain component must fit precisely, including the adapter plate. Unfortunately, some DIYers use a plate that wasn’t made for their specific combination.

The Symptoms: An adapter plate that’s even a little off can cause parts shifting out of place, gears catching, power loss and even total system failure.

The Fix: Change the adapter plate to one that matches your project. Advance Adapters guarantees each kit includes the correct plate for the listed transmission-engine-transfer case combination.

Using Low-Quality Parts

The Problem: The adapter plate and hardware must be able to handle the drivetrain forces. Some manufacturers use materials like stud-grade steel and cast aluminum, which aren’t strong enough for heavy-duty driving.

The Symptoms: Poorly-made adapters and hardware wear out faster and are more likely to cause shifting issues. They cost less upfront, but you pay for it later.

The Fix: Get a high-quality adapter made of strong materials such as billet aluminum, cast iron or high-strength steel to ensure durability.

Torque Converter Seating

The Problem: Automatic transmissions use a torque converter to transfer engine power. You need to remove the torque converter to install the adapter, and sometimes DIYers don’t seat it correctly when reinstalling.

The Symptoms: The converter won’t engage properly, so shifting is difficult or delayed. The converter may even come off the transmission pump.

The Fix: Reinstall the converter by greasing or lubricating the snout and sliding it onto the splines. Turn clockwise until you feel the converter clunk twice. The gap between the flex plate and converter should be between 1/8 and 3/16 inches; use spacers if necessary.

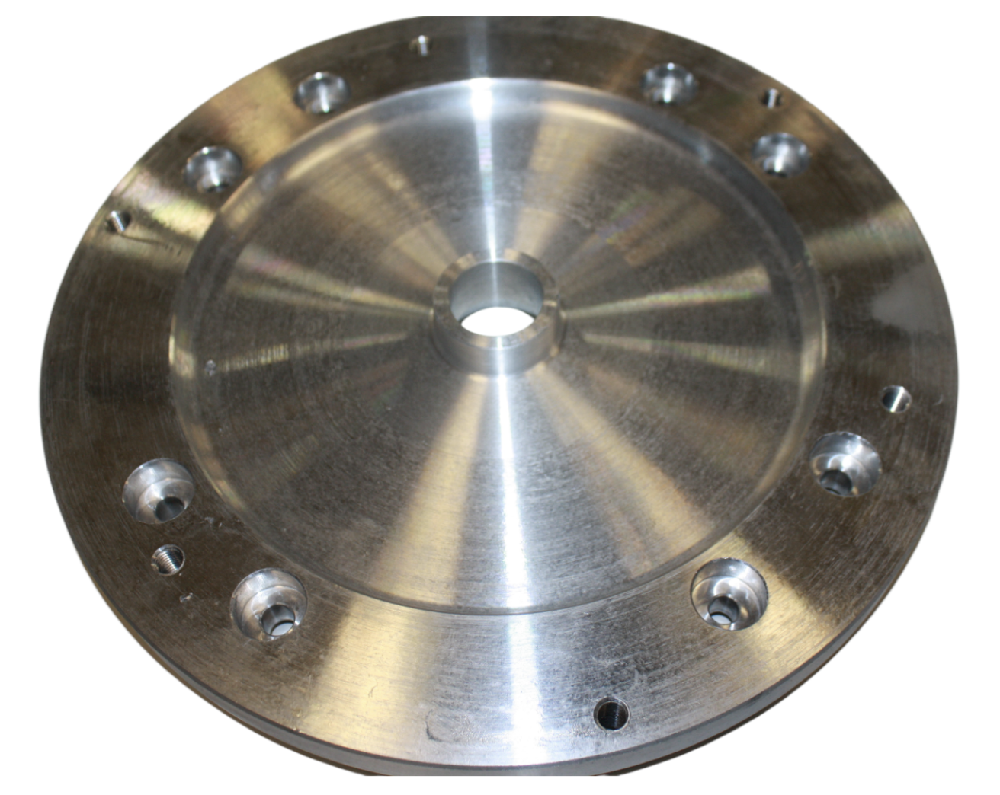

Broken Flex Plate

The Problem: Some automatic transmission adapters have a setup where the flex plate is no longer bolted to the torque converter. When this happens, it removes the support the flex plate needs, leaving it prone to bending and breaking.

The Symptoms: Signs of a damaged flex plate include heavy vibrations, strange noises while idling and shifting, power loss at high speeds and trouble starting the engine.

The Fix: One solution is bolting the flex plate to the flywheel. Another is using a stronger flex plate. In both situations, get the assembly re-balanced for the best performance.