Wth the Atlas transfer case being such a diverse case fitting into such a wide variety of vehicles, naturally we needed a variety of available transfer case yokes.

All of our yoke options are called out by their series number, and style.

Series Number

The series number is a classification that was standardized by the Spicer corporation that refers to the size of the yokes bearing width and cap diameter.

Yokes we offer are:

1310CV, 32 spline A1310CV

1330CV, 32 spline A1330CV

1350CV, 32 spline A1350CV

1310, 32 spline A1310

1350, 32 spline A1350

1410, 32 spline strap A1410

1410, 32 spline U-Bolt A1410U

1310/1330/1350 FLANGE YOKE, 32 spline AF1300

(1300 series Flange yoke is drilled and tapped for (4) 1/2"x 20 bolts on a 4.25"diameter,(4) 7/16"x 20 bolts on a 3.50"diameter and has a 2.0" male index for the mating yoke.)

Spicer companion yoke numbers are as follows:

(1310 C.V., P/N 211229x), (1310 non-C.V., P/N 2-2-939), (1330 C.V. - P/N 211631x), (1330 non-C.V., P/N 2-2-1369), (1350 C.V., P/N 212024x), (1350 non-C.V., P/N 3-2-1579).

1350,1410 FLANGE YOKE CV, 32 spline AF1350 ( Yoke has a 3.125" male index for the mating yoke.)

1350,1410 FLANGE YOKE non CV, 32 spline AF1410

(1410 Flange yoke is drilled and tapped for (4) 12mm x 1.25 bolts on a 3.75"diameter and has a 2.75" female index for the mating yoke.)

1410 non C.V. flange yoke. Spicer companion yoke number is 3-2-1329 (1410 non-C.V.)

1350,1410 FLANGE YOKE non CV, 32 spline AF1410STD

(Flange yoke is drilled and tapped for (4) 7/16-20 bolts, 2.75" female index for the mating yoke.)

1480FLANGE YOKE, 32 spline AF1480

TOYOTA FLANGE YOKE (3 BOLT PATTERNS 60mm x 60mm, 64mm x 56mm, & 68.3 x 60mm) AFTOY

JEEP JL FLANGE YOKE TO RETAIN THE STOCK GKN DRIVE SHAFTS AFJL

Flange yoke may require the companion flange bolts to be installed through the yoke before the yoke is installed onto the transfer case. This depends on the series of companion yokes used. If the flange yoke is currently installed on your transfer case, you may be required to first loosen the yoke retaining nut, then pull the yoke away from the transfer case enough to install the companion flange bolts. Once the bolts are in place, a new yoke lock nut should always be installed and torqued to 150 ft.-lbs. to secure the yoke to the transfer case.

Size Chart

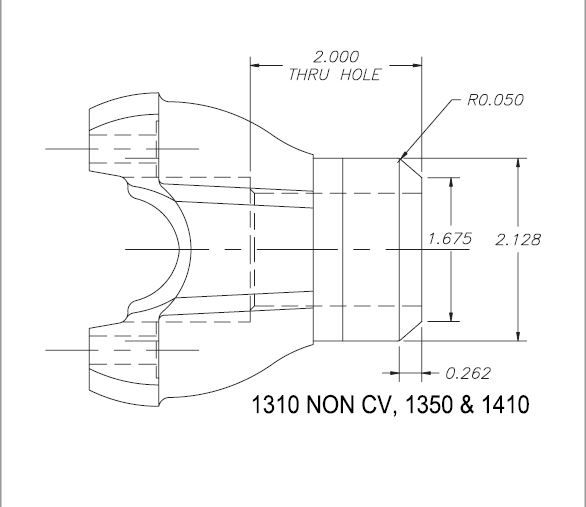

| Spicer Series # | Cap Diameter | Width Across Caps |

| 1310 | 1.062 | 3.219 |

| 1330 | 1.062 | 3.625 |

| 1350 | 1.188 | 3.625 |

| 1410 | 1.188 | 4.188 |

Yoke Style

The two common yoke styles are CV (Constant Velocity) also referred to a "Double Cardan" and Non-CV. The CV style utilizes a carrier block (Cardan) that contains a set of two bearings, one per side. One side of the carrier (Cardan) is bolted to the transfer case output yoke, capturing a bearing between the transfer case output yoke and one side of the carrier, and the other bearing is captured between the other side of the carrier and the yoke affixed to the drive shaft. This type of yoke setup is most commonly used when attempting to overcome step or compound drive shaft angles.

The Non-CV style yoke uses only one bearing that is secured between the transfer case output yoke and the drive shaft yoke using straps or u-bolts.

Yoke Modifications: Changing the style of yokes on the Atlas transfer case may require your new yoke to be modified. When installed on an Atlas, the yoke will load up against a tapered roller bearing. Some yokes require a chamfer to be machined for clearance on this caged bearing. All the yokes we offer have this chamfer.

Advance Adapters has started a change in product design with the mating components of its rear output shaft, front output shafts, and on divorced unit front input shaft.

These updates started in 2017 with the new flat tow option on the Atlas and expanded into 2018 to include the standard Atlas 2 speed and 4 speed.

The flat tow rear output shaft is numbered 317124, setting it apart for recognition as the newer design. The standard design Atlas shafts were updated in 2018 are numbered 318124, 318123, 318016A. We kept the ending 3 digits the same as the earlier shafts. These new shafts completely superceded the old design.

These shafts will normally be part of a assembly bill of materials that we have labeled as a -T or -G2,G3 at the end of the assembly part number.

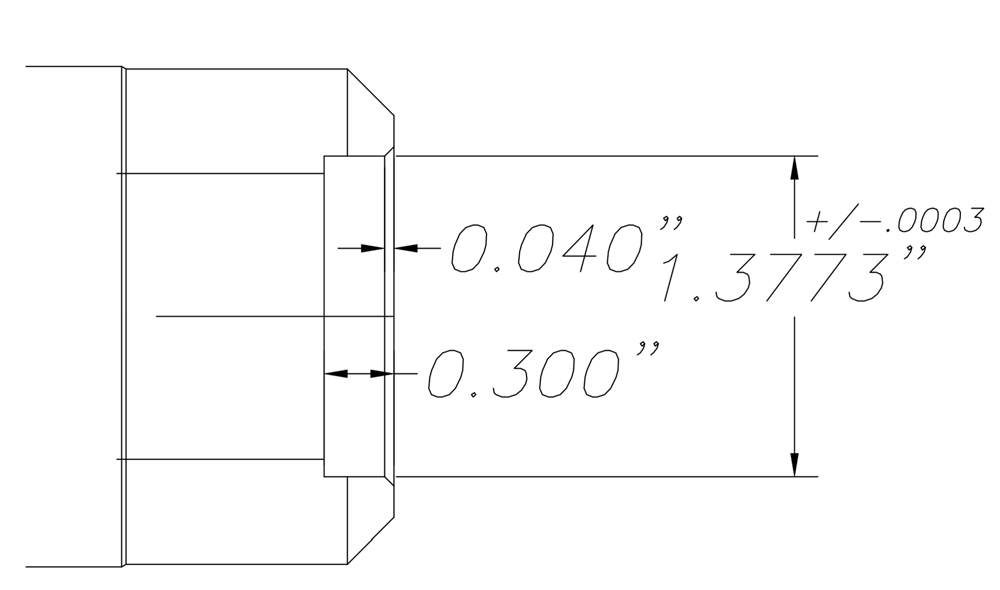

The updated shafts will require an update to the yoke to work correctly.

The updated shafts will require the yoke to have a counter bore for indexing to the shaft. All of the yokes we produce have this counter bore. The simplicity of this design, all current yokes will work fine on ALL earlier shaft applications. Any yoke that is not counter bored WILL NOT WORK on the new style shafts.

Summary:

All Advance Adapters shafts, New and Old will work with the yokes that are counter bored.

Old yokes NOT counter bored will still work on the older shaft, but would require the counter bore to work on the new design shafts.

_1000.jpeg)